MEtAL PROCESSINg For OUR SOLUTIONS

Every step of the production needs to planned carefully and in detail. We use high quality materials that need to undergo different processes to build the final product.

EDGE BENDING

Edge bending, also known as press braking or flanging, is a metalworking process where a piece of sheet metal is bent along a straight line to form desired angles and shapes.

- Precision: Ensures accurate bends for high-quality results

- Versatility: Applicable to various materials and thicknesses

- Customization: Tailored to specific project requirements

POWDER COATING

Powder coating is a finishing process where a dry powder is applied to a surface and then cured under heat to form a protective and decorative layer.

- Durability: Provides a long-lasting, resistant finish

- Variety: Available in numerous colors and textures

- Environmentally Friendly: Produces less waste and fewer pollutants compared to traditional liquid coatings

METAL PROCESSING FOR MECHANICAL SOLUTIONS

Metal processing is crucial in the development of mechanical solutions. It forms the foundation that ensures the stability and precision of components. Without advanced metal processing techniques and accurate manufacturing, the reliability and durability of modern mechanical systems would not be possible.

PUNCH PRESS

A punch press is a machine used in metalworking to cut or shape material by applying pressure through a punch.

- Precision: Allows for accurate cutting and shaping of materials

- Efficiency: Capable of high-speed, repetitive operations

- Versatility: Suitable for various materials and thicknesses

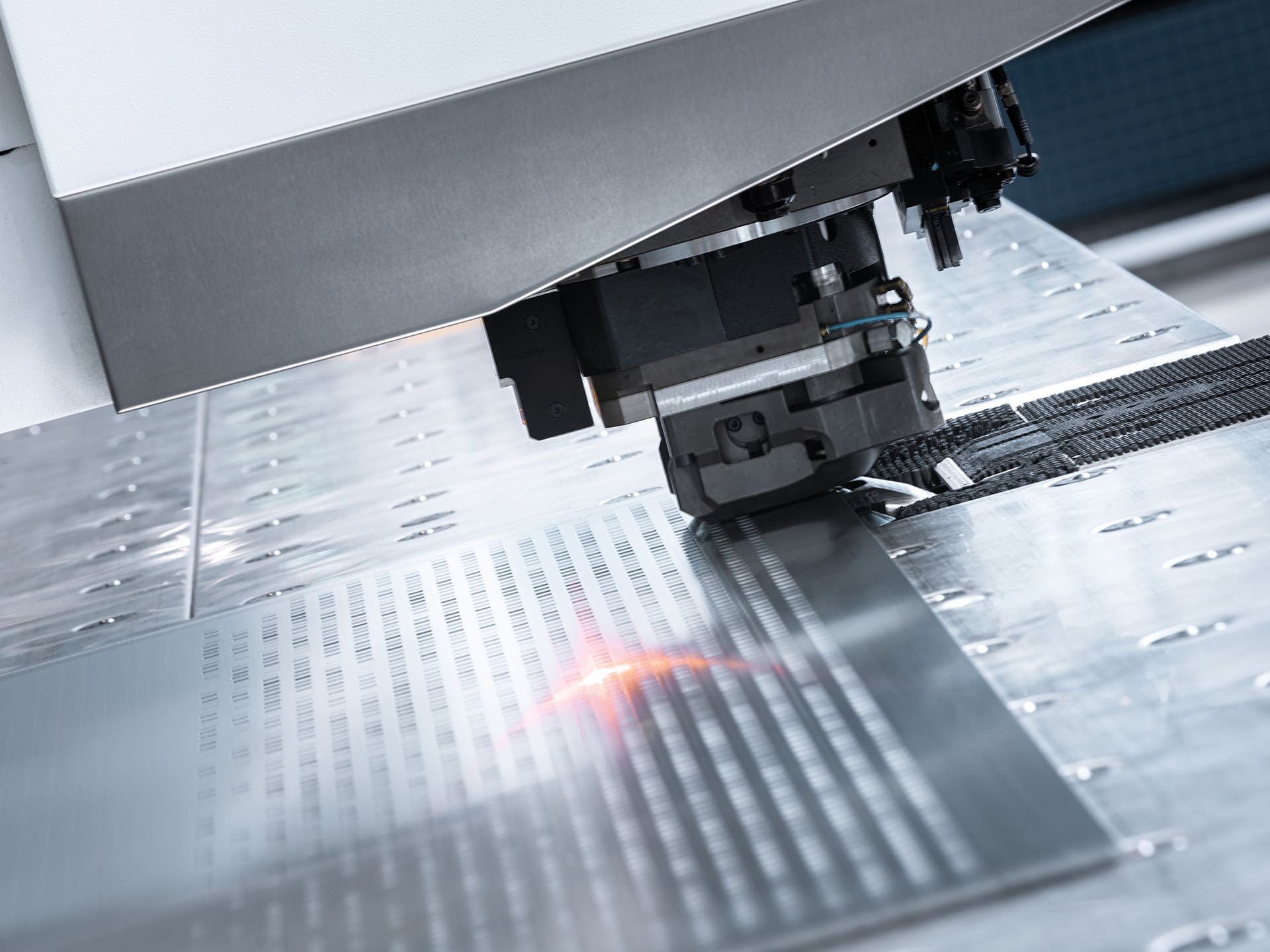

2D LASER CUTTING MACHINES

A 2D laser cutting machine is a cutting tool that uses a focused laser beam to cut and shape sheet metal with high precision.

- Smooth Edges: Produces clean cuts

- Minimal Waste: Maximizes material usage with precise cuts

- Complex Shapes: Capable of creating intricate designs and patterns

TUBE LASER

A tube laser is a cutting tool that uses a focused laser beam to cut and shape metal tubes with high precision.

- Enhanced Flexibility: Ideal for cutting various shapes and sizes of tubes

- High-Speed Processing: Efficiently handles large production volumes

- Precision Cutting: Achieves accurate and intricate cuts on tubular materials